Employees

Annual Review 2023

Circle of Progress

Welcome

Million Euros in Annual Sales

Countries

Business Groups

Companies

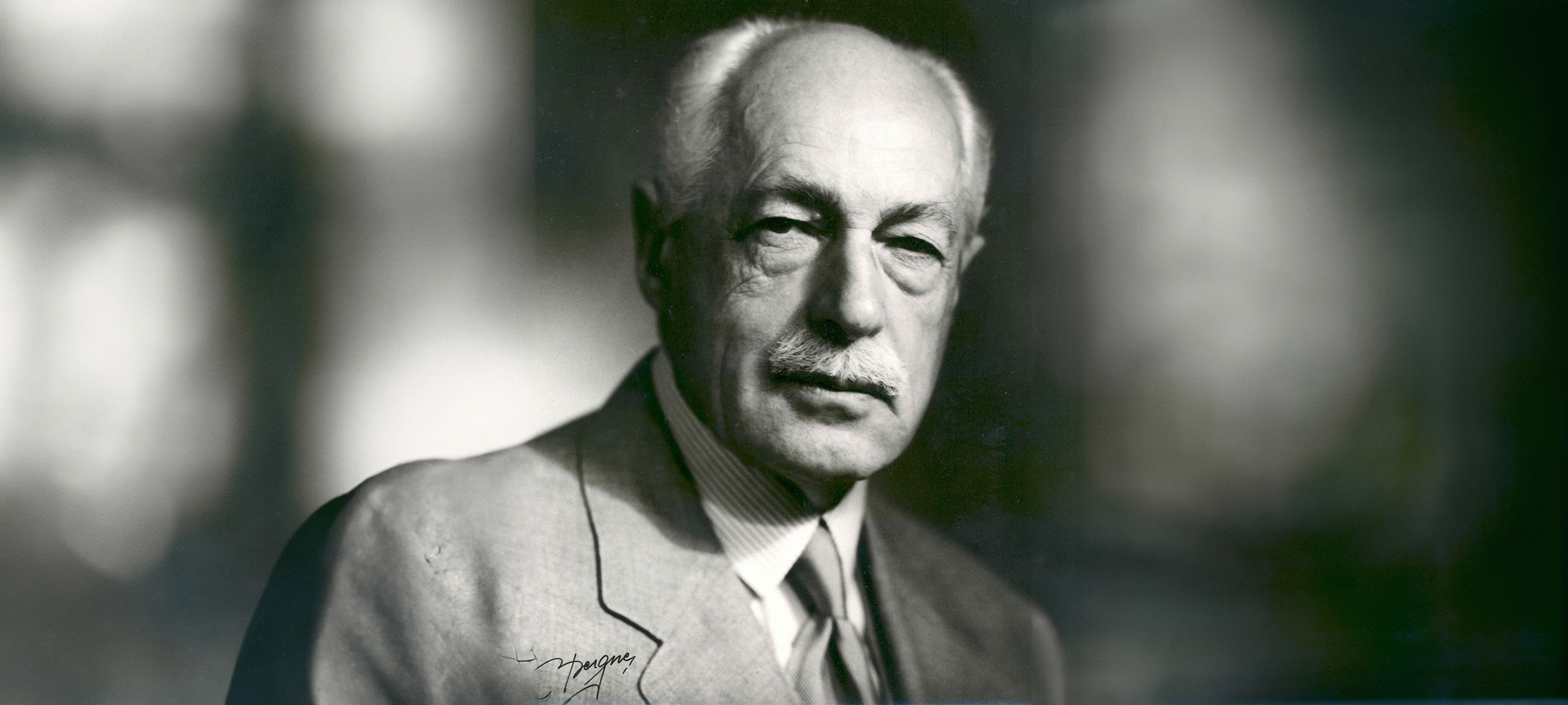

150 Years of Industry Presence — Building on a Family Legacy

Vision, determination, and agility creates resilience and sets the prerequisites for growth. The combination of a solid strategy and flexibility to adjust when the world changes has been increasingly important over many years now.

Read CEO Summary

The core of Axel Johnson International’s identity is captured in the term decentralisation. This essentially means that decision-making happens within the business groups and companies. The local companies make decisions close to their market and customers, forming exceptional partnerships within their respective sectors.

Explore Growth Strategy

Business Model and Strategic Focus

Securing Long-Term Growth

At the core of the sustainability work lies a profound recognition of the positive change the group can collectively drive. It’s not merely about compliance, it’s about being relevant and adopting long-term approaches to conducting business and sustaining success.

Explore Sustainability

Creating Impact

Making Things Happen

Committed to Long-Term Business

Performance Overview

Being part of Sweden’s largest privately owned corporate group, we are built on a strong family legacy. A group with a clear value-driven, entrepreneurial culture, and a commitment to an inclusive working environment and a diverse workforce.

Explore People & Culture

A Place to Grow and Develop

Equality to Foster Innovative Teams

A few years ago we moved towards a more centralised IT function, to ensure the same standard across the group. As a result, all group companies have now transitioned to the Microsoft 365 (M365) suite, facilitating enhanced cybersecurity and data accessibility.

Explore Digitalisation

A Proactive Digital Strategy

Navigating the Digital Landscape

The Business Groups

Read more

Read more

Read more

Read more

Read more

Read more

Get to know some of our companies in these articles that highlights sustainability and showcases innovative solutions across our group. Stories that exemplifies how our companies drive change and collaborate with partners throughout the value chain to find sustainable solutions.

Circular Approach to Bearing Reuse

Forankra Group Raises the Bar in Circularity

How Team Spirit Solved a Conveyor Challenge

Sunny Outlook for Water Supply in South Africa

Win-Win with Remotorisation

Workplace Safety with Know-how

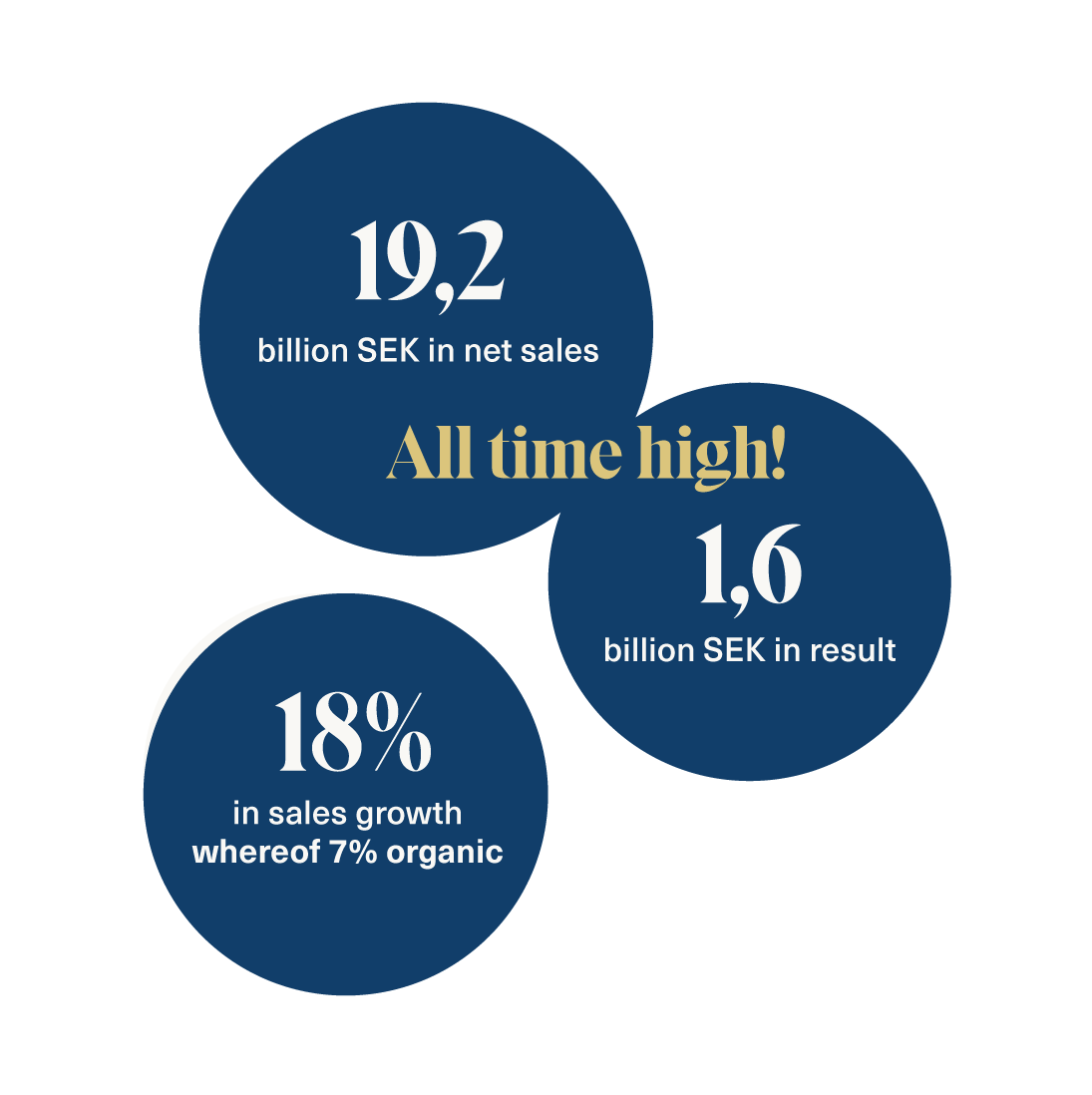

The year began with various continued challenges, from supply-chain disruptions caused by the pandemic and ongoing global conflicts to increasing inflation and general market uncertainty.

Explore Financial Overview

A Year of Resilience

Two Steps Ahead with Financing

Financial Overview

Axel Johnson International is a privately owned Swedish global industrial group with over 200 companies operating in selected niche markets within the industrial sector. The core mission is focused on nurturing and acquiring businesses specifically centered on technical components and industrial solutions.

Previous

Previous